CNC Foam Cutter Machine Retrofit

Overview

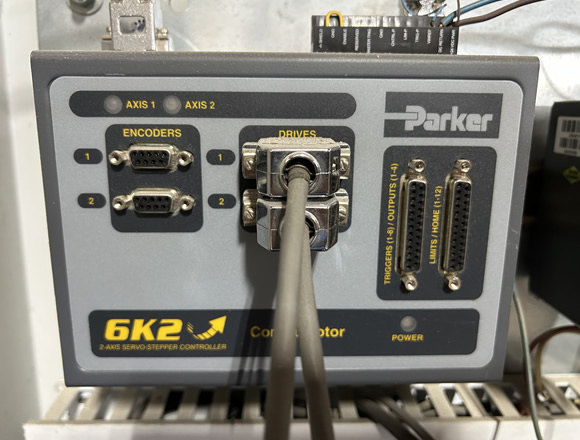

Xemog Technologies Inc. recently undertook a significant project involving the retrofit of a CNC foam cutter machine. The machine, which had been a staple in the client's production process for many years, was equipped with an obsolete motion controller that was no longer supported, causing frequent downtimes and inefficiencies. Recognizing the need for an upgrade, the client approached Xemog Technologies with the goal of modernizing their equipment to improve performance and reduce costs.

The Challenge

The primary challenge of this project was to replace the outdated motion controller with a modern one that would be compatible with Windows 11. Additionally, the client required a new Human-Machine Interface (HMI) terminal to enhance usability and control. The existing system's obsolescence not only hindered productivity but also posed a risk to the continuity of operations, as spare parts and technical support were increasingly difficult to find.

The Solution

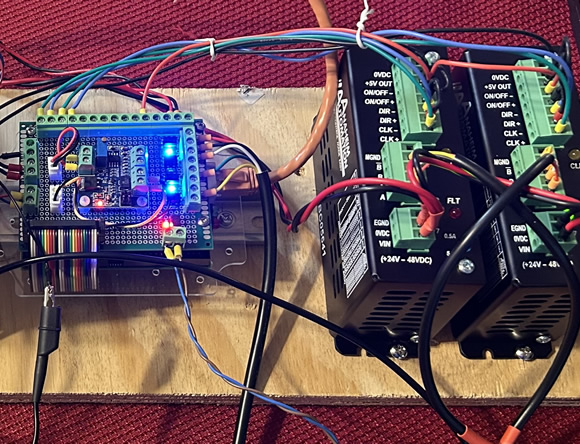

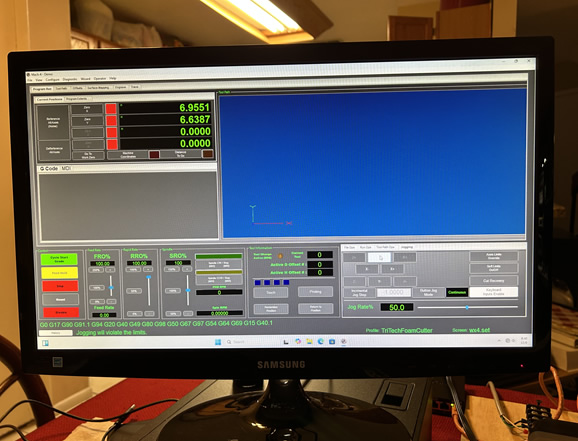

Xemog Technologies' team of experts conducted a thorough assessment of the existing system and devised a comprehensive retrofit plan. The obsolete motion controller was replaced with a state-of-the-art model that offered enhanced precision, reliability, and compatibility with Windows 11. The new HMI terminal was designed to provide intuitive control, enabling operators to manage and monitor the machine with ease.

Implementation

The retrofit process was meticulously planned to minimize downtime and disruption to the client's operations. The old motion controller was carefully removed, and the new controller was installed and configured. Extensive testing was conducted to ensure seamless integration with the existing machine components. The new HMI terminal was also installed, featuring a user-friendly interface that allowed for real-time monitoring and control of the CNC foam cutter machine.

Results

The retrofit project was completed successfully, resulting in significant improvements in the machine's performance and reliability. The modern motion controller and new HMI terminal not only enhanced the machine's capabilities but also reduced the risk of future downtimes. The client reported a substantial increase in productivity and efficiency, as well as a reduction in maintenance costs.

Cost Savings

One of the most notable outcomes of the project was the cost savings achieved. By upgrading the obsolete system, the client was able to save more than $40,000 in potential repair and maintenance costs over the next few years. The investment in modern technology proved to be a cost-effective solution that delivered immediate and long-term benefits.

Conclusion

The CNC foam cutter machine retrofit project by Xemog Technologies Inc. exemplifies the transformative impact of modernizing outdated equipment. By replacing the obsolete motion controller and installing a new HMI terminal, the client experienced enhanced performance, increased productivity, and significant cost savings. This case study highlights the importance of embracing technological advancements to maintain operational efficiency and competitiveness in today's rapidly evolving industrial landscape.